- Farm Infrastructure >

- Storage & Conveying >

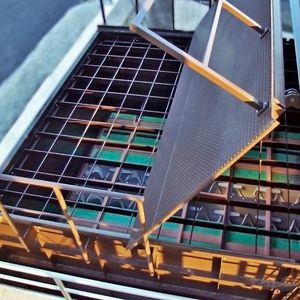

- Unloading receiving hopper

Unloading receiving hoppers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... widest range of harvest receiving hoppers The range of PELLENC PERA ŒNOPROCESS harvest receiving hoppers is suitable for any type of installation and allows a regular ...

Our AGRITREMIE hoppers are available in three different capacities, starting from 2 Mc. up to 22 Mc.; in addiction, they can also be surmounted by corrugated sheet metal ferrules. The circular shape guarantees an easy ...

Unloading trailers: The GKR unloading hopper is available in three widths. Depending on the type of goods and the required line capacity, 800, 1200 and 1600mm belts are available. Standard ...

RECEIVING HOPPER: unload and receive quickly your bulk products DESCRIPTION: The receiving hopper allows you to easily and safety receive your bulk products such ...

The unloading hopper (also called truck unloader) is an essential solution to simplify and accelerate the unloading process of semi-trailers and trucks transporting bulk. ** Operational ...

... your storage process The Miedema receiving hoppers form the basis for reliable storage. The receiving hopper serves as a buffer and provides the cleaning and, if desired, ...

Dewulf Group

Bottom Trailer Unloading attachment for nuts and potatoes. Place underneath truck bottom unloading dock.

... filling device for feeders. The Murska Crimp Feeder features a robust 6 m3 hopper, a twin-lane grain transfer from hopper to spiral, and a reliable elevator conveyor from hopper to feeder. ...

... intake hopper has a module structure: PS220-KP-3.0- intake hopper module, 3m length, without the driving set PS220-KP-AKC- the intake hopper’s accessories The hopper ...

.Gentle receiving due to placement in a water bath .Reduced damage to field crops .Gentle pre-cleaning through injection of air – resulting in more efficient main wash .Automatic control of desludging .Easy-to-remove ...

The modular receiving pit made by SILESFOR DP make much easier the construction of mansonry necessary on receiving pits; in effects the metallic and hot galvanized structure, is based on two vertical ...

The buckling construction on the discharge side of the moving floor ensures an optimally dosed transition between the receiving hopper and the product cleaner. The moving floor consists ...

Bijlsma Hercules B.V.

... Nut flow rate from 0,5 T/h to 15 T/h Supplied in removable trailer version on wheel Discharge width 3300 mm Discharge height of the cross belt 1550 mm Hopper belt DG200 = 14 m² ...

Breston hoppers guarantee durability and reliability. The hopper forms the heart of the intake line and is used as receiving, cleaning and/or sorting plant. •Robust & compact •Easy ...

Receiving systems Advantages -Low wear -Sturdy, provenconstruction -Variable discharge capacity -Direct weighing -Filling volume 20 - 80 m³ -Foldable roof construction High discharge ...

The infrastructure of the grain receiving function is becoming increasingly centralized. This results in increasing demands imposed on the capacity of the conveyor system, from receiving until in the ...

The DOWNS SUPERCHARGER potato receiving hopper has been designed to receive the crop and to constantly feed the grader. This solution makes it possible to increase the work output by 25 %: the piling ...

... the auger feed hopper is to feed any type of production system. CONSTRUCTION Metal supporting frame with galvanized metal profiles Deep-drawn metal tubes, with bolted composing elements Spiral in carbon steel Product ...

Three horizontal feeding augers transporting grain into unloading vertical auger, which reload it into other transport. Auger spirals made by special steel from Italy, which ideally centered before installation, so that ...

Zavod Kobzarenka Ltd.

Usually works as a piece of sorting line. It’s used for unloading trailers and transports with farm produce to another machines from line, sorters for example. Container with 2,5 – 3 t capacity, transfer belt by width ...

The receiving systems from HUNING Anlagenbau are distinguished by their high discharge capacity along with low wear. Filling takes place through the top side of the container. To protect from coarse impurities ...

The Allround VP Receiving Hopper is designed to feed, or act as a buffer in loading and unloading lines or processing lines. The hopper is designed in such a way that ...

Allround Vegetable Processing B.V.

The Receiving Hopper is built for side and/or backtipping. RH 2000/2700 are used for fast unloading by backtipping. Mod RH 12 S is used for sidetipping. The Receiving ...

EMVE Sweden AB

... hygiene and minimal cleaning • Bolted design OPTIONS • Level indicator • Load carrying gratings • Side protection for receiving pit

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how AgriExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining