- Products

- Catalogs

- News & Trends

- Exhibitions

Mounted wood chipper Slantelectric

Add to favorites

Compare this product

Characteristics

- Type

- mounted

- Engine type

- electric

Description

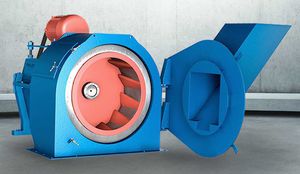

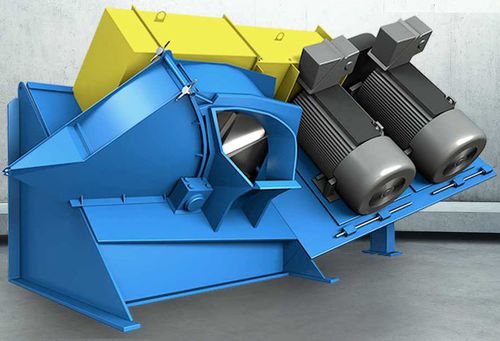

SLANT DISC CHIPPER

Uniform chips from waste wood or whole logs are produced in the Acrowood Slant Disc Chipper. These machines have been in operation for decades and are proven to save mills money by requiring little maintenance while producing high-quality fiber with minimal pins and fines.

Slant Disc Chippers Features

•Better chip quality results from the stable feeding and chipping action—a result of less movement in the spout

•Minimal pins and fines are generated with the accurate knife-to-anvil adjustment

•No damage to the chips on exit through the clear discharge path, minimizing pins and fines

•Replaceable wear plates on the chipper disc surface

•Factory installed knife style options include conventional Babbitted knives, and commercially-available disposable knife systems

•Reduced maintenance man-hours—most knife changes can be handled by one man from the front of the chipper disc

•Outstanding bearing life results from hollow shaft, fixed arbor design

•Sizes from 52″ to 84″ disc diameter available

•Uniformly sized conventional pulp chips as well as mini- and macro-chips

Slant Disc Chip Quality

Chip quality, installed costs and maintenance costs are the criteria by which all chippers should be measured. Yet they are rarely met by a single machine – until now. Until, that is, the Acrowood Slant Disc Chipper.

Acrowood’s Slant Disc Chippers produce a high-yield, uniform chip quality with low capital investment and low maintenance cost. In fact, it is often cheaper to install a new Acrowood Slant Disc Chipper than to fix an old chipper that needs rebuilding!

A pivoting casing quadrant provides unobstructed access to the chipper disc for knife changes.

VIDEO

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.