- Products

- Catalogs

- News & Trends

- Exhibitions

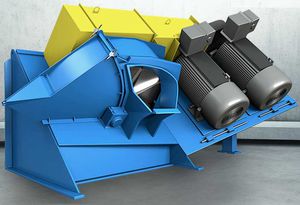

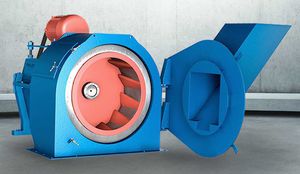

Mounted wood chipper Veneer electric

Add to favorites

Compare this product

Characteristics

- Type

- mounted

- Engine type

- electric

Description

VENEER CHIPPER AND FEEDWORKS

The Acrowood Veneer Chipper-Long and High Capacity Feedworks transforms waste veneer into high-quality chips that can be sold or used for multiple purposes. Dramatically increase your yield of usable fiber in converting waste veneer to chips by using an Acrowood VCL and HC Feedworks, tested and proven for over 40 years.

Veneer Chipper & Feedworks Features

•Higher yield of usable chips produced in the Acrowood VCL Veneer Chipper and HC Feedworks than any other veneer chipper

•Rigid, high strength chipper base

•Stable and strong bearing pedestals facilitate adjustment of the thrust bearing

•Chip impact and damage is reduced by extra deep chipper casing

•Less power requirements with pivoting arm design: weight of the rolls provide the cracking force and reduces pressure needs

•Veneer held stable for the highest chip quality by crush roll and fingers of the high-capacity feedworks

Produces Long Chips

The Acrowood Veneer Chipper is specially designed to produce chips from waste veneer. The design of the chipper disc, arbor, and base produces an ideal arrangement so that the knife passes in the correct orientation relative to the anvil and anvil base. This chipper is not suitable for chipping cores or other forms of waste wood, as the knife and anvil arrangement is wrong for these other applications.

VIDEO

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.