- Products

- Catalogs

- News & Trends

- Exhibitions

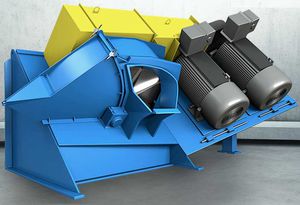

Mounted wood chipper electric

Add to favorites

Compare this product

Characteristics

- Type

- mounted

- Engine type

- electric

Description

THE RECHIPPER

The Acrowood Rechipper is designed to reduce oversized chips to a smaller size. Chips slide down the flat-bottomed spout which uses the full length of knife and anvil for chipping. With excellent oversize chip reduction and high capacity, the Acrowood Rechipper is a superior choice for overs processing in the wood room.

Rechipper Features

•42″ or 61″ diameter discs available

•Flat bottomed spout for full use of anvil width

•10 knives for excellent oversize chip reduction with high capacity

•Gravity feed with options for bottom or overhead discharge

•Heavy-duty, face-mounted, babbitt adjusted knives

•Simple infeed spout

•Easily mounted, 4-bolt, pillow block bearings

•Easy knife access

Excellence in Chip Processing

Acrowood Rechippers are designed to reduce oversized chips to an acceptable size for pulping with minimal generation of pins or fines.

For maximum effectiveness chips would ideally be oriented so that the long axis of the chip would be perpendicular to the cut, and the resulting 2 pieces would each be half the length (approx.) of the original chip.

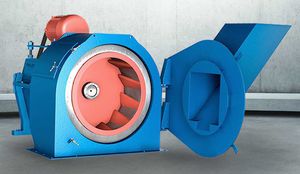

Rechipper Machine Options

•42” or 61” discs are both available with 10 knife installation.

•Overhead or bottom discharge configurations available.

•Heavy-duty, face-mounted, Babbitt adjusted knives

•Simple infeed spout

•Easily accessed, 4-bolt, pillow block bearings

•42” rechipper 50 HP – 3,600 lb. less motor Capacity—10-12 uph (~20 GTPH) (~50-70 m3/hr)

•61” rechipper 100 HP – 7,000 lb. less motor Capacity—18-20 uph (~40 GTPH) (~100-115 m3/hr)

VIDEO

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.