- Products

- Catalogs

- News & Trends

- Exhibitions

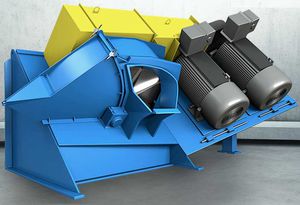

Mounted wood chipper Crackerelectric

Add to favorites

Compare this product

Characteristics

- Type

- mounted

- Engine type

- electric

Description

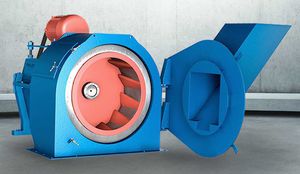

CHIP CRACKER

The Acrowood Chip Cracker processes overthick chips while minimizing fiber degradation, pins, and fines generation, and without damage to accept chips to ensuring higher pulp yield from overthick chips. The Chip Cracker processes high volumes of wood chips fed between the two large rolls, gently cracking them for chemical pulping operations.

Chip Cracker Features

•High performance cracking of overthick chips for liquor penetration in pulping applications

•Reliable, long-lasting rolls have keyed, replaceable segments formed of cast stainless steel

•Trouble free operation with minimal maintenance

•Very few pins, fines or damaged chips generated with low-profile knurl pattern

•Less power requirements with pivoting arm design: weight of the rolls provide the cracking force and reduces pressure needs

•A single motor drives both rolls through twin, foot-mounted gear boxes and heavy-duty universal joint drive lines

•Low maintenance man hours

•Less susceptible to damage from contaminants

•Roll shaft segments easily accessible

•Easy roll removal and bearing replacement

•Roll shaft assemblies accessible through side frames

•Long-life stainless steel segments on a square shaft

•Minimal hydraulic requirements

VIDEO

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.