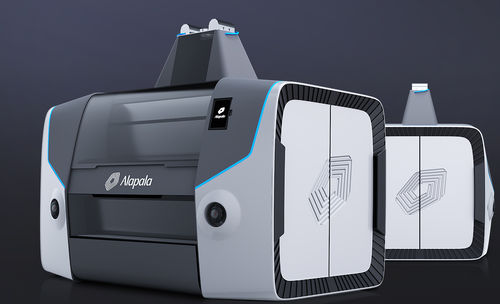

Roller mill Similago IIcornbarleywheat

Add to favorites

Compare this product

Characteristics

- Application

- corn, barley, wheat, sorghum

- Type

- roller

- Other characteristics

- horizontal

Description

The new SIMILAGO II is the result of ALAPALA’s 60 years of experience in the milling technology and engineering of roller mills and the complete range of milling machinery. The SIMILAGO II is designed for high, continuous and consistent grinding of cereals such as wheat, maize (corn), rye, spelt, barley and sorghum. A uniform feed rate across the grinding rolls ensures a consistent grind.

Feeding Control Systems

Stock Level Control

The product level at the inlet bunker is controlled by using load cells, which sends signals via PLC to adjust the feed roll speed accordingly.

Feeding Gap Adjustment

Manual feeding gap adjustment mechanism ensures a uniform flow on feed rolls.

Grinding Control Systems

Motor Load Protection

Main motor load is constantly measured for protection against any possible damage.

Roll Disengagement System

The system disengages main rolls after the machine shutdown, for preventing any product blockage at the next start-up.

Roll Speed Monitoring

The rotational speed of grinding rolls is monitored against an unexpected stop due to belt problem, etc.

VIDEO

Catalogs

Related Searches

- Grain grinding mill

- Top-tailer

- Screw elevator

- Feed elevator

- Vegetable crop cleaning machine

- Automatic sorting machine

- Seed crop cleaning machine

- Seed sorting machine

- Roller grinding mill

- Bucket elevator

- Cereal crop cleaning machine

- Corn grinding mill

- Feed-mill unit

- Vertical bucket elevator

- Barley grinding mill

- Wheat grinding mill

- Sorting machine with cleaning system

- Maize crop cleaning machine

- Soybean crop cleaning machine

- Sorghum mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.