- Farm Infrastructure

- Storage & Conveying

- Roller grader

- Allround Vegetable Processing B.V.

- Products

- Catalogs

- News & Trends

- Exhibitions

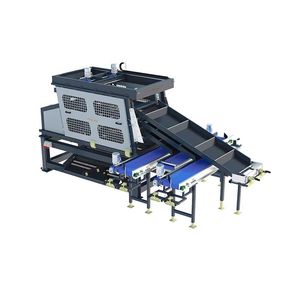

Roller grader R 80

Add to favorites

Compare this product

Characteristics

- Technology

- roller

- Grading width

1,250 mm

(49 in)

Description

The Allround Radial grader is equipped with lateral placed grading rolls out of stainless steel.

The distance between these rolls changes in steps over the different grading stages. Conveyor belts are placed under the machine, one for each grading size. When the distance between the rollers changes above the size sections, every second roller lowers its position. This ensures a proper positioning of the product between the rollers. The speed is adjustable by frequency control, and the machine is equipped with a special greasing system.

TYPES AND SPECIFICATIONS

R 80

Length:Depending on the model

Width:1250 mm

Height:1720 mm (adjustable)

Options

Radial graders come up with options that include brusher, electrical adjustment, rubber flap, rubber mat, size indication and safety switches. See More Images

Stainless steel plating

If needed, the machine can be fitted with stainless steel plating.

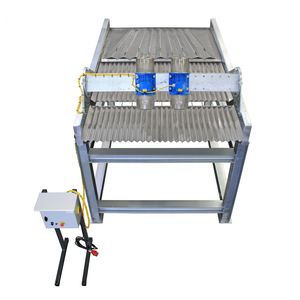

Brush

When dry products are graded, it is necessary to opt for the optional brush. This brush cleans the rollers of the machine from dirt or dust that sticks to the rollers when grading dry products.

Reverse switch on the transport belts

In some cases it is needed that the outlet belts of the grading machines are able to transport produce to two sides. Therefore, Allround VP offers an optional reverse switch for the transport belts.

Fall dampers

When the belts directly fill boxes, optional fall dampers can be fitted to reduce the falling height.

Bag holder

Customers may choose to fill bags directly from the grading machine. For this situation, Allround VP offers a bag holder to simplify this process.

Other Allround Vegetable Processing B.V. products

Grading

Related Searches

- Belt elevator

- Stationary dryer

- Inclined elevator

- Mobile elevator

- Top-tailer

- Feed elevator

- Mobile dryer

- Vegetable crop cleaning machine

- Automatic sorting table

- Receiving chute

- Box rotator

- Vegetable sorting table

- Fixed dryer

- Height-adjustable elevator

- Flexible elevator

- Fruit conveyor

- Rotary drum cleaner

- Potato elevator

- Vegetable receiving hopper

- Potato haulm separator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.