- Farm Infrastructure

- Storage & Conveying

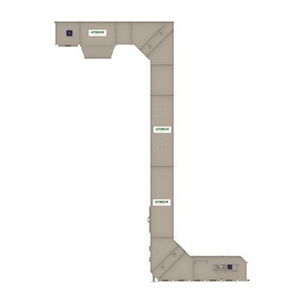

- Grain conveyor

- ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS

- Products

- Catalogs

- News & Trends

- Exhibitions

Grain conveyor BK 400-500-650beltroller

Add to favorites

Compare this product

Characteristics

- Applications

- for grain

- Technology

- belt, roller

Description

Medium capacity conveyors. Up to 400 m³/h

ALTINBILEK Closed Belt Conveyor ensures the horizontal or sloped conveyance of the product to be transported. The conveyance is performed via the belt traveling on the conveyor roller. They are manufactured as one-roller, two-roller, or three-roller system, depending on the product to be conveyed and the capacity. Oneroller systems are mainly used to convey packages and sacks. Tworoller and three-roller systems are suitable for the products in powder and granular form at high capacity. Drive drum is rubber coated to prevent skidding. Weighted belt-tensioning system is incorporated in long conveyance distances. Impact absorbing rollers are used at the

feeding point. The standard production is painted steel, galvanized steel or optional stainless steel.

FEATURES

•Completely Bolted Joint

•Easy-to-assemble Body Structure

•Maximum Endurance

•High-strength EP Belt

DRIVE SYSTEMS

•Drive System Mountable at Right or Left

•Power Transmission with Belt-Pulley Connection (Standard)

•Hollow shaft for reducer motor (Optional)

•Full shaft for reducer motor and Coupling (Optional)

•Industrial Reducer with Auxiliary Drive (Optional)

Catalogs

No catalogs are available for this product.

See all of ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS products

Grain Handling Equipments

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.