- Farm Infrastructure

- Storage & Conveying

- Grain conveyor

- ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS

- Products

- Catalogs

- News & Trends

- Exhibitions

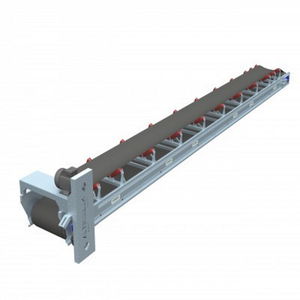

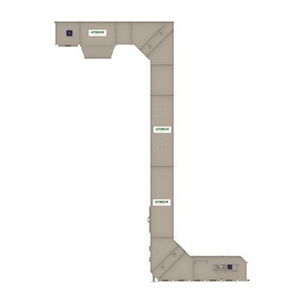

Grain conveyor UH 150-200-250screwtubular

Add to favorites

Compare this product

Characteristics

- Applications

- for grain

- Technology

- screw

- Other characteristic

- tubular

Description

ALTINBILEK Screw Conveyor , ensures the horizontal, sloped, or vertical transport of the powder and granule products. It is used in conveyance for feeding, distribution, collection, mixing, dosing, and discharging purposes. There are 2 types of screw conveyors: U-type (Hull) and Tube Type, both of which are helical and are manufactured as galvanized steel, painted steel, and stainless steel depending on the requirement. Used in all branches of industry

•Foods

Flour, Rice, Tea, Sugar, Milk Powder, Various Powders, Flakes, and Granules

•Animal Feeds and Cereals

Wheat, Barley, Corn, Oil Seeds, Various Feeds, Pellets, and Flakes

•Chemicals and Minerals

Cement, Sand, Glass Crumb, Ash, Limestone, Ore, Coal, Salt, Fine

and Natural Dust, Flakes, Granules

•Biomass and Waste

Wood Pellets, Chips, RDF, Rubber, Plastics, Other Flakes, Pellets,

and Granules

FEATURES

•U-Type or Tube-Type Body Structure

•Heavy Duty Type

•Synthetic Intermediary Bearings

•Impermeable Dust Seals

•Easy Maintenance and Simple Installation

•Silent and Vibration-free Operation

DRIVE SYSTEM

•Direct Drive with Reducer Motor and Chain Coupling (Standard)

•Power Transmission with Belt-Pulley Connection (Optional)

•Power Transmission with Chain Connection (Optional)

SECURITY SYSTEM

•Speed Guard Sensor (Standard)

•Excessive-product Detection Sensor (Standard)

•Roller Heat Detection Sensor (Optional)

•Roller Pulse Detection Sensor (Optional)

•Product Flow Detection Sensor (Optional)

Catalogs

SCREW CONVEYOR UH150-200-250

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Other ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS products

Grain Handling Equipments

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.