- Farm Infrastructure

- Storage & Conveying

- Rice crop cleaning machine

- ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS

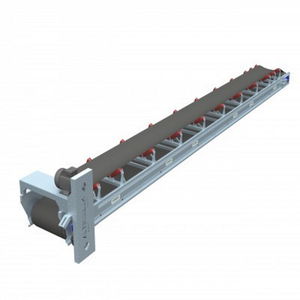

Rotary drum cleaner ADC seriesseedricesoybean

Add to favorites

Compare this product

Characteristics

- Crop type

- seed, rice, soybean

- Other characteristic

- rotary drum

Description

ALTINBİLEK Drum Sieves are used for cleaning products such as barley, wheat, corn, oats, rice, soy, sunflower, canola, and legumes. Slight foreign matters are cleaned through aspiration. The product goes through the sieve holes of various diameters Large foreign matters come out of the drum end. Thanks to cleaning, unwanted materials such as stalk, straw, wood chips, corn cob pieces, garbage do not damage other equipment. Applications like such as rough cleaning, precision cleaning, seed cleaning and grading etc. can be performed for cereal and leguminous seeds. The product flow is better due to the continuous rotational motion. It is more sensitive and lighter than Vibro sieves, and its maintenance is easy. The sieves have a self-cleaning feature. It is capable of separating large foreign matters without clogging the sieve’s inlet and outlet. With their unique design and strong structure, Altinbilek drum sieves provide high efficiency and low energy consumption. Hole diameters depend on the product. Sieve can be replaced rapidly from easy-to-open side cover. The sieves clean themselves during sieving via wooden rollers. Drum angle can be adjusted according to the foreign matter in the product to be sieved, and the angular adjustment is made by a manual or motorized movement mechanism. The rotational speed of the drum can be adjusted electronically. During operation, sorting can

be controlled by taking samples from the control points.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS‘s catalogsOther ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS products

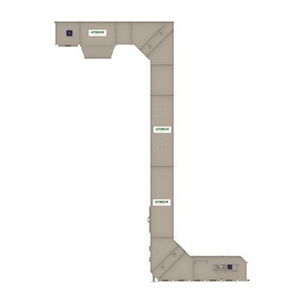

Grain Handling Equipments

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.