Grain mill 1254rollerwith screw conveyorvertical

Add to favorites

Compare this product

Characteristics

- Application

- grain

- Type

- roller

- Other characteristics

- with screw conveyor, vertical

Description

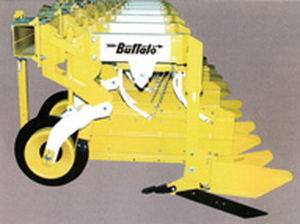

Built with the operator in mind, our Roller Mills are easy to adjust, easy to operate and easy to maintain.

-Capacities: 700 to over 4500 bushels per hour - among the highest capacity on the market

-Easy-adjustment lever for setting the rolls for coarse or fine crack

-Each Roller Mill comes with magnets as standard equipment on the inlet hopper to prevent metallic debris from getting into the gain

-Each Roller Mill is available as either a stationary or trailer-mounted unit

-Trailer-mounted models allow conveniently moving the mill to various processing sites

-Stationary-mounted models allow permanent installation

-Rolls are heat-treated to Rockwell C-62 - some of the hardest in the industry

-Henke Roller Mills come in a wide variety of roll sizes from 18" to 54" in length

-Discharge choices include: elevator, belt or blower

-24" wide discharge belt conveyor moves the processed grain away quickly and works well for filling trench silos

-Elevator discharge moves the milled grain up for discharge into a wagon, etc.

-Blower discharge model is available for cracking HMC (high-moisture corn) and blowing it into vertical silos

-Easy access shields for ease in service and maintenance

-Standard one-to-one ratio drive produces a finished product with minimum fines; optional differential drive is also available for a finer rolled finished product

-Two-high Roller Mills are available featuring coarse-corrugated top rolls and fine-corrugated bottom rolls to allow for additional particle size reduction

VIDEO

Catalogs

No catalogs are available for this product.

See all of apache‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.