- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Animal feed mill hammer

Add to favorites

Compare this product

Characteristics

- Application

- for animal feed

- Type

- hammer

Description

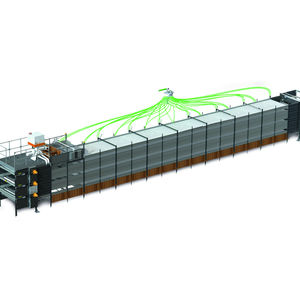

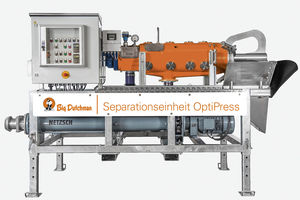

The Big Dutchman hammer mills operate with a driving power of 11 to 45 kW. Depending on the requirements, for example fine milling or feed with more structure, different mills and screens are used. The special milling control system ensures that the dosing auger correctly supplies the mill with the type of material that is to be milled. This means that the delivery rate is automatically adapted to the type of material conveyed.

The type of mill installed (single, double or parallel mill) depends on the throughput requirements. The milled meal can be transported by means of different conveyor elements (bucket or chain elevators or trough augers).

Main advantages

-high capacity, also for fine milling;

-uniform feed structure;

-milling takes place in both directions: even wear of the screens;

-screen cleaner and metal collector for a high performance and longer service life of the mill;

-rugged design;

-dust filter for better hygiene;

-easy maintenance and a long service life of screen and hammers;

-all parts of the mill are mounted onto a frame, minimising the installation requirements on site;

-cooling of the milled feed.

Catalogs

No catalogs are available for this product.

See all of Big Dutchman‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.