- Small Farm Equipment

- Small farm tool

- Seed sieve

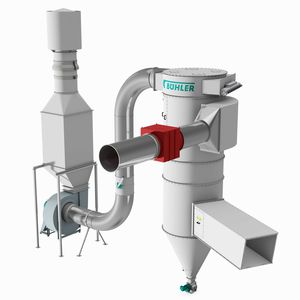

- Bühler Group

Seed sifter machine for animal feed

Add to favorites

Compare this product

Characteristics

- Type

- seed, for animal feed

Description

Sieving machine

A versatile sieving machine for powder and granulates, designed for top sanitation and food safety. It is used as a control screen in gravity spouting in milling, brewing, bakeries and food processing – to check fatty and sticky flours or sugars.

Flexible configuration

Wide range of applications

Available as a single or double unit. Screen holes range from 0.75 to 8 mm to adapt to different raw materials, such as whole wheat flour, bakery flour, biscuit flour, maize starch, crystal sugar and durum wheat. Magnets come in various strengths to comply with different food safety regulations.

Cleaning and maintenance

Designed for quick and easy use

You can unlock the cleaning hatch in one movement, meaning that it takes less than 15 seconds to access the sieve and product area for inspection and cleaning. You can clean the sieve in 30 seconds.

Sieving machine for maximum food safety.

Hygienic design, easy control.

The sieving machine MKZK is designed to be used with free-falling bulk materials. It removes

foreign matter from powders and granulates with maximum safety thus ensuring top food safety.

Top sanitation.

All parts that come into contact with product are made of

stainless steel. The hygiene-optimized design lowers the amount

of residues and improves access for cleaning tremendously.

Reduced energy consumption.

The belt-free direct drive reduces energy consumption by at

least 5 % in comparison to the previous model. Thanks to the

fl ow-optimized design the consumption of aspiration air can

be reduced by no less than 30 %.

Catalogs

No catalogs are available for this product.

See all of Bühler Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.