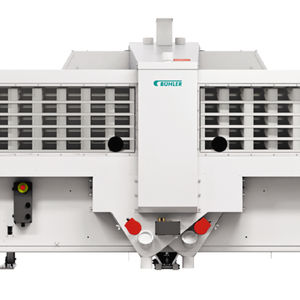

Destoner MTCG

Add to favorites

Compare this product

Description

Combistoner

The combistoner MTCG is a high-throughput classifier and destoner. It efficiently separates stones, glass and other foreign objects from many types of grain, including wheat, durum, corn, rye, oats, barley and rice.

How does the combistoner work?

The combistoner classifies and destones in a 2-step cleaning process

The combistoner is a highly efficient, high-throughput grain cleaner. It first classifies the grain into high-density and mixed fractions. The mixed fraction then moves onto the next step of the milling process. The high-density fraction is reprocessed in the destoner, where foreign objects such as stones, metal and glass are removed from the grain.

Wide range of throughput and applications

Use the combistoner to process many different grains

The combistoner cleans a wide range of grain, including wheat, barley, maize, rye, oats and rice. It also has a wide capacity range, processing between 10 to 28 tons of wheat an hour.

Airflow

Add an optional MANW air-recycling unit to reduce energy

Fit an optional MANW air-recycling unit to reduce energy consumption by up to 30%, by returning filtered process air back into the process. The air-recycling unit also operates with a small exhaust air volume, central filtering system and aspiration system, saving space and investment costs. It can also reduce maintenance and downtime, by cleaning more small particles from the process air.

Catalogs

No catalogs are available for this product.

See all of Bühler Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.