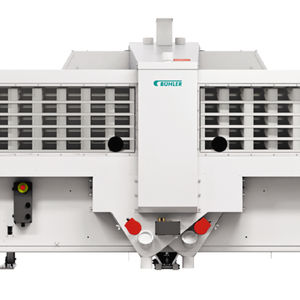

Lentil dehuller Pulsroll®peabean

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Crop type

- pea, lentil, bean

Description

The Pulsroll huller DRHG is designed to effectively remove the seed coats of a wide range of pulses. The Pulsroll is a high throughput solution, offering improved yields, a uniform finish and optimum quality.

Improved yields and product quality

Adjustable sieves and stones for consistent hulling

The emery stones come in four sections so that you can replace each section individually. The optional interchangeable sieve system offers further hulling quality. The sieves can be adjusted to ensure a uniform milling surface. You can also reduce the amount of dust and brokens by adjusting the milling pressure using the outlet counterweights and machine inclination.

Flexibility in hulling

Hulling of different types of pulses

The grinding gap, emery stone grits, sieves and machine inclination can be individually adjusted. This makes it possible to hull many different types and shapes of pulses.

Robustness

Designed for maximum uptime and low maintenance costs

The Pulsroll has a sturdy design. The wear parts are designed to protect the machine from abrasive products. The emery stones offer high resistance and handle up to 10,000 tons of product in their lifetime.

High throughput

Hulling up to 4 tons of pulses per hour

The Pulsroll can hull up to 4 tons of pulses per hour. Various motor sizes ranging between 11 kW and 18 kW are available.

Catalogs

No catalogs are available for this product.

See all of Bühler Group‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.