- Products

- Automatic packing machine

- Bühler Group

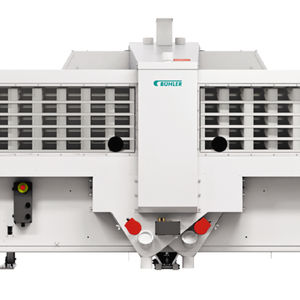

Automatic packing machine CHRONOS OML-1060 B

Add to favorites

Compare this product

Characteristics

- Other characteristics

- automatic

Description

The first fully automatic bagging station from BTEC, Bühler and Premier Tech's joint venture, packs 20–50 kg bags with free-flowing granular products such as feed, pet food, rice, seeds or plastic pellets with throughputs of up to 600 bags per hour.

High precision, cost-effective fully automatic bagging station

Enhanced productivity

A fully automatic solution

Rely on an effective solution to handle bagging processes fully automatically. Thanks to various sensors and machine intelligence, the location of the top of the bag is always known - from the bag separation to the bag closing and sewing – leaving no chance for failure.

Maximize availability

Reliable and carefree bagging

Flexible and carefree operation ensures maximum uptime. The system is designed for changing over recipes in minutes and provides robust handling of various bag types.

Ensure safety

Remarkable safety standards

High safety standards and smart risk mitigation are the new normal. The bagging station is equipped with guards and safety switches to protect operators at all times. The system is designed for hygienic processing with wide maintenance doors and stainless steel surfaces.

Catalogs

No catalogs are available for this product.

See all of Bühler Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.