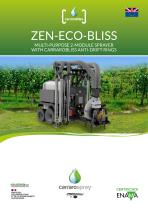

Towed sprayer ZEN-ECO-BLISSfor viticultureeco-friendly

Add to favorites

Compare this product

Characteristics

- Mobility

- towed

- Application

- for viticulture

- Other characteristics

- eco-friendly

Description

Confined tunnel sprayer for drift reduction. Treatment height 1000, 1250 or 1500 mm

VIDEO

Catalogs

ZEN-ECO BLISS

7 Pages

Related Searches

- Weed sprayer

- Tractor-mounted sprayer

- Folding arms weed sprayer

- Hydraulic weed sprayer

- Pull-type sprayer

- Vineyard sprayer

- Orchard agricultural atomizer

- Weed sprayer with diaphragm pump

- Garden sprayer

- Sprayer with piston pump

- Air blast sprayer

- Self-propelled crop sprayer

- Battery-powered sprayer

- Sprayer with combustion engine

- Greenhouse sprayer

- Cannon sprayer

- Disinfection sprayer

- Push sprayer

- Autonomous sprayer

- Eco-friendly sprayer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.