- Livestock Farming

- Milking equipment

- Vacuum milking pulsator

- CoPulsation Milking System

- Products

- Catalogs

- News & Trends

- Exhibitions

Vacuum milking pulsator 60/40

Add to favorites

Compare this product

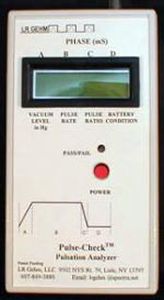

Characteristics

- Type

- vacuum

- Pulsation ratio

- 60/40

Description

The CoPulsation™ Milking System is an innovative pulsation system that consists of pulsators, controlling electronics for power the pulstors, shells, liners and splitter Tees. This product is easily installed and maintained and can replace any existing pulsation system. It is in use on farms ranging in size from small ones with bucket milkers to large parlors milking thousands of animals 24 hours a day. CoPulsation™ is the only humane way to milk an animal with a machine as it provides a gentle compressive massage action on the teat during the rest phase that is most similar to the sucking action of a newborn.

Mastitis remains the most costly problem in the dairy industry in spite of decades of research and focus on management activities such as cleanliness and milking procedures. It must be recognized that the primary cause of mastitis is the milking machine as it is the item that is responsible for damaging the teat canals and creating the environment enabling the invasion of bacteria. The milking machine is responsible for the application of vacuum, extraction of milk and the required resting of the teat.

There is an abundance of evidence supporting the fact that milking machine design, in particular pulsation, is responsible for mastitis. The manufacturers of conventional milking machines have provided detailed evidence of the numerous problems with their products in issued patent documents. A simple observation of dairy cows on any farm provides a basis of that evidence. First calf heifers first exposed to the milking process typically milk very quickly and completely.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.