- Farm Management

- Software

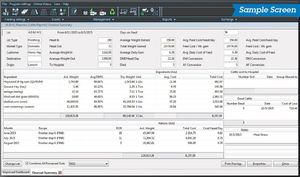

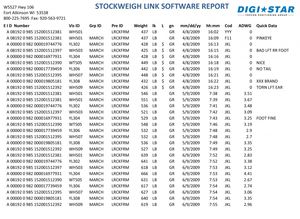

- Data management software

- Digi-Star International

Data management software RF Datalinkfeed

Add to favorites

Compare this product

Characteristics

- Function

- data management

- Applications

- feed

Description

•Automatically manages the transfer of your feeding information

•Continuously looks for pen-fed data and feeding vehicle readiness to receive the next ration and/or pen feeding information

•System utilizes 900 MHz or 2.4 GHz base radio to transfer data

•Monitor scale indicator from your PC with full key control

•Send text messages from your PC to the scale indicator display

•Perfect for operations with two or more mixers and operations using stationary mixers or batch boxes

•Communications range up to one mile, depending on location

RF DataLink options & benefits:

•Load by Load: Send pre-determined loads to specific pens one load at a time, or send all loads to trucks

•List Mode: Send all ingredients, all recipes and all pens to trucks. You select which ration, volume and pens to feed

•Bunk Reader: DataLink accepts recipes, loads and pens to feed from third party Bunk Reader software and sends to trucks

•Sort loads by various recipe and mixer combinations – even create delivery zones per truck

•Recipe loading efficiency: Load half of ingredients in stationary mixer and half in the mixer truck, at the same time – reducing loading times

•Flexible: multiple feeding process options

•Multi-languages

•Auto-start program

•Manage load-by-load ingredient loading and pen feeding information

•Send all pen feeding data – Operator manages pen feeding

•Manage ingredient data to stationary mixer or batch box

•Send pen list to delivery truck

•Links to third party Bunk Read software

Catalogs

Other Digi-Star International products

Software / Data Transfer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.