- Products

- Catalogs

- News & Trends

- Exhibitions

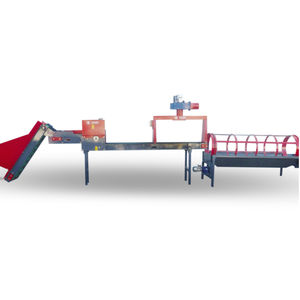

Garlic sheller E600

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Crop type

- garlic

- Production capacity

Min.: 600 kg/h

(1,322.77 lb/h)Max.: 800 kg/h

(1,763.7 lb/h)

Description

Solutions adapted to your needs. Your garlic quality preserved with our innovated and technical systems.

The garlic bulbs are placed in the hopper, a ridged feeding belt feeds the splitting unit.

The garlic is split between a two specially designed soft belts. Brushes help to finish the splitting process before an optimal manual finishing. A suction removes all the skins and waste to leave the clean cloves to be graded.

The E600 splitter has a total power of 6Kw 380v threephase, this machine is made of the following units:

A feeding unit

- Moto variator 0.37Kw 380v threephase

- A 150kg hopper (Large feeding hopper on request)

A splitting unit

- Two specially designed belts, the top one is adjustable to adapt to the different grades.

- Seven rows of finishing brushes

A 4kw 380v threephase skin & waste suction unit with power adjustment

A manual finishing belt for 4 to 8 people

- A 0,25Kw 380v threphase motoreducer (moto variator on request)

- At the end of the belt, a overhead unit is connected to the main suction to remove the small remaining waste (a second suction unit is available on request)

A clove grading drum

- Grade 1: 23mm

Machine output: 600Kg/h to 800Kg/h

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.