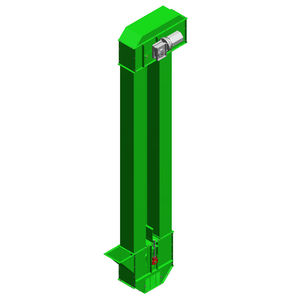

Nuts dryer ES seriestowerwith belt conveyorelectrically-powered

Add to favorites

Compare this product

Characteristics

- Application

- nuts

- Mobility

- tower

- Other characteristics

- with belt conveyor, electrically-powered

- Capacity

Max.: 30 m³

(1,059 ft³)Min.: 2 m³

(71 ft³)

Description

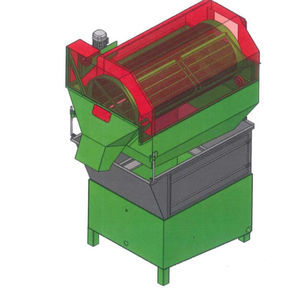

FACMA’s dryer offers a simple, cheap and necessary solution for the drying of woody shell products (hazelnuts, walnuts, almonds, etc.). The models start from a minimum capacity of 4,5 m³ to a maximum of 33 m³, they can be laid out in series reaching the requested capacity. The dryer can be loaded by conveyor belt or bucket elevator. The desiccation is obtained by the forced ventilation of hot air, which the heat-exchanger sends to the ventilator, which at the same time pushes it inside the body of the dryer. The product, continuously ventilated, is mixed by a central Archimedean screw and it can be ventilated also with non heated air. When the grade of humidity of the product is the requested one, the same product is extracted, by gravity, from the inferior part of the storage bin through the shutter and it is moved away by an adequate transport system. This process permits to considerably reduce the drying cycle, to maintain the product’s organoleptic qualities unchanged, assuring at the same time the worker’s safety in obedience to the laws in force.

Catalogs

No catalogs are available for this product.

See all of Facma‘s catalogsRelated Searches

- Belt elevator

- Stationary dryer

- Inclined elevator

- Mobile elevator

- Screw elevator

- Top-tailer

- Bucket elevator

- Tower dryer

- Height-adjustable elevator

- Fruit conveyor

- Vertical bucket elevator

- Automatic grader

- Dryer with belt conveyor

- Nuts dryer

- Inspection grader

- Electrically-powered dryer

- Automatic crop cleaning machine

- Nuts crop cleaning machine

- Sorting conveyor

- Crop cleaning machine with cleaning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.