- Products

- Catalogs

- News & Trends

- Exhibitions

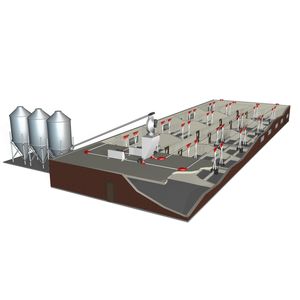

Poultry feeding equipement EasyBatchwith weighing scale

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Animal type

- for poultry

- Other characteristic

- with weighing scale

Description

A major cost item on your farm is feed. So it’s no surprise that managing feed costs efficiently is a particular focus area. An automatic feeding system helps you to accurately control the amount of feed given. Feed, water and light are synchronised under all circumstances to promote optimal animal growth. The feed composition can be easily adapted to suit the animals' needs, This saves time and helps you keep the cost price of feed and the production results under control.

How does a feed weigher work?

A feed weighing system uses an electronic feed weigher positioned between the silo and the hoppers in the house to accurately dispense small feed rations. The system accurately controls the entire process, from preparing the feed in the batch weigher, filling the hoppers in the house right up to supplying the feeding lines in the house.

The storage hoppers in the house are filled with feed. As soon as the feeding process starts, the feed is transported from the hoppers to the animals. At the same time, a new portion of feed is prepared in the feed weigher, based on the number of grams per animal per day. This can also be prepared the right mixing ratio if you wish. If one of the silos empties during feed preparation, the system automatically switches to the other silo containing the same type of feed. The daily amount of feed and the mixing ratio can be pre-set in a feed curve.

EasyBatch is especially for situations where feed mixing is not necessary. EasyBatch controls 1 or 2 houses with maximum 2 silos and registers the consumption of five different feed types.

Catalogs

book broilers

28 Pages

book layers

29 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.