Maximum productivity per operator

Transplanting machine for plants in modules (diameter from 2 cm[0.8 to 5.5 cm [2.16)

1 operator

for row

■Perfect for vegetables such as tomatoes, brassicas, celery, peppers all other vegetables having leaves similar to ones above listed with min height 10 cm [4 and max height 30 cm [12

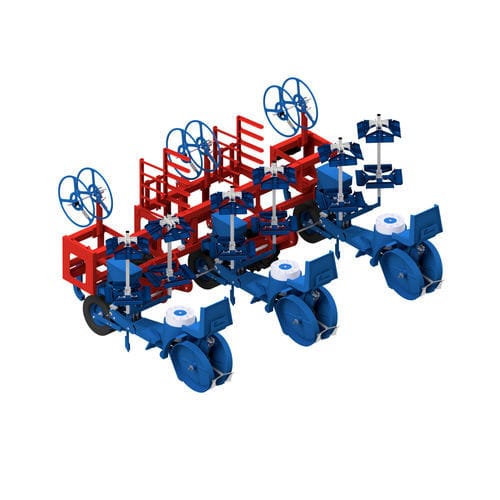

■Versions: 3 point hitch, draw-bar

■Frame: rigid, folding, telescopic

■min row spacing: 46 cm [18 (35 cm [14 with longer element - 25 cm [10 tandem version)

■PSC (Hydraulic gearbox as an alternative to the mechanical one with display to set plants per hectare / distance on the row)

■Main fittings: parallel linkage, rubber roller, granular applicator, fertilizer applicator, water applicator, water pipe, stretching tool, hydraulic transmission, back pressing wheel hydraulic adjustament

This carousel machine can be fed with plugs of different shapes (pyramid, cylinder, cone and, in some cases, square blocks). The transplanter carousel is turning in clockmotion (STOP&GO).

This specific feature is extremely important to guarantee a constant drop of the plants from the top to the ground. The clockmotion allows to increase the performance per hour, the precision of the planting depth and the distance in the row.