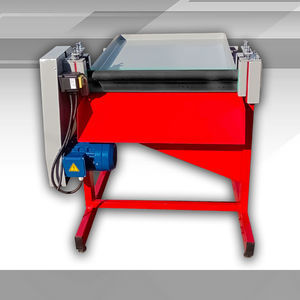

Broad bean dehuller GOBOA1000automatic

Add to favorites

Compare this product

Characteristics

- Crop type

- broad bean

- Other characteristic

- automatic

Description

High-performance broad bean shelling and damage reduction:

The GOBOA1000 automatic broad bean sheller is an advanced machine for shelling broad bean pods with an average output of around 400kg and a damage reduction of up to around 3%. The high pea shelling capacity is due to the independent belt system and the high-grade rubber compound of the pea shelling rollers. There are no pressure belt pockets on the machine, and the belt area is not restricted in any way, making it possible to shell irregularly shaped pods (conjoined, crooked) without worrying about the possibility of machine downtime due to a pod getting stuck in the pocket.

New type of high-grade rubber compound:

Changes in regulations for rubber manufacturers have forced a change in the additives used, so that the rubber has started to lose its properties more quickly. We now use a two-layer compound coating of the highest quality available as a guarantee of longer service life.

Basic equipment:

•Buffer hopper.

•Two-layer coating of rubber compounds of the highest available quality.

•Rollers with two layers of rubber with different characteristics and an external structure to increase friction force.

•Pressure belt system with no dead zones utilises 100% of the sheller roller width and reduces grain damage to approx. 3%

•Vibrating table with extended troughs with larger vibration motors (increase in vibration force by more than 150%).

•Infinitely adjustable shelling speed

•Infinitely adjustable

Optional equipment:

•Return module - modular conveyor with screening table for returning unshelled pods back to the vibrating table.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.