- Products

- Catalogs

- News & Trends

- Exhibitions

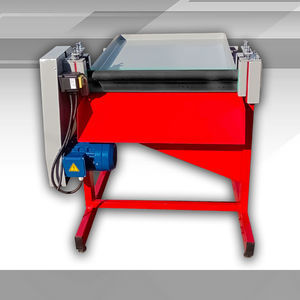

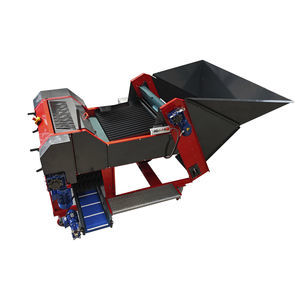

Grain conveyor T300beltinclined

Add to favorites

Compare this product

Characteristics

- Applications

- for grain

- Technology

- belt

- Other characteristic

- inclined

Description

Don't waste time cleaning up:

The T300 shelling conveyor is used to transport the shells generated during the shelling of broad beans to the trailer. The amount of shells created during the operation of an automatic broad bean sheller is up to several metres 3 of waste per hour. The use of the conveyor effectively reduces the time required for cleaning.

Choose the right length:

The T300 sheller conveyor comes in three versions with lengths of 3m, 4m and 5m with break through. The 3m basic version of the T300 is recommended for handling trailers with a side height of up to 1400mm. The 4m long version of the T300-4 will work well for trailers with sideboard heights up to 2000mm. The largest shell conveyor, the T300-5, thanks to its design with a horizontal break in the last 80cm of its length, allows it to feed wider trailers and heights of more than 2000mm.

Belt always on axis:

WAll of our belt conveyors are fitted with a belt with a pre-vulcanised guide wedge. This complicates the construction of the conveyor and makes it more time-consuming to make, but always results in trouble-free operation and no need to adjust the conveyor from time to time to make the belt run evenly on the drums..

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.