- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

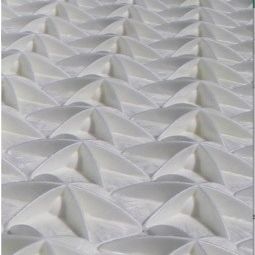

Irrigation basin floating cover for manurefor wastewater treatment basinsplastic

Add to favorites

Compare this product

Characteristics

- Application

- irrigation basin, for manure, for wastewater treatment basins

- Material

- plastic

- Other characteristic

- for irrigation, evaporation, heat-loss, biogas

Description

The unique and patented Hexa-Cover® Floating Cover is perfect for almost any type of Oil & Gas and API applications.

The Hexa-Cover® Oil & Gas / API products has proven to be an effective and efficient option for hot heavy oil duty applications such as CHOPS, Diluted Bitumen SAGD.

Hexa-Cover® OIL & Gas Duty is:

•Reduce emissions such as BTEX benzene, Toluene, Ethylbenzene and Xylene. Eliminate or reduce water vapour that act as a carrier of VOCs that add to odour problems

•Reduce heat loss resulting in lower operating costs. Insulation for liquid surface in a heated crude oil tank lowers operating costs for CHOPS facilities and central processing batteries.

•Reduce offensive and carcinogenic BTEX odours.

•Reduce tank head space corrosion by lower levels of humidity above the liquid level.

•Reduce or possibly eliminate expensive defoaming chemicals.

•Reduce energy needed to reach optimum process temperatures.

•Reduce the amount of water vapour generated as steam. Steam causes icing of the thief hatch and the transport of other odours from the tank.

Hexa-Cover® OIL & Gas Duty is:

•Chemically compatible with heavy oil components up to temperatures of 100 °C and for SAGD dilbit sales tanks

•Resistant to weight gain

•Polymer is anti-static surface with a value of 3.7 x 1009 Ω

•Resistant to thermal shock. Tested at -40 °C to +100 °C for sudden rapid temperature exposure

•Can be installed while existing tanks are in operation

Oil & Gas Applications for Hexa-Cover® Products

•Conventional Crude Oil

•Frac Oil

•Gasoline, Diesel and other Refined Products

•Thermal Heavy Oil

•SAGD Dilbit Sales Tanks

•Sour Sand Slurry Tanks

•Process Water Ponds

•Purified Tailings Ponds

VIDEO

Catalogs

No catalogs are available for this product.

See all of Hexa-Cover A/S‘s catalogsRelated Searches

- Shade ball

- Reservoir floating cover

- UV protection floating cover

- Evaporation floating cover

- Plastic shade ball

- Irrigation floating cover

- Biogas floating cover

- Manure floating cover

- Prevent evaporation shade ball

- Hexagonal floating cover

- Odor control shade ball

- Anti algae floating cover

- Anti-algae floating cover

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.