- Farm Infrastructure

- Storage & Conveying

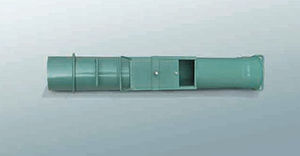

- Grain conveyor

- Horstkötter GmbH & Co. KG Tornado

- Products

- Catalogs

- News & Trends

- Exhibitions

Grain conveyor TRF serieschainflexible

Add to favorites

Compare this product

Characteristics

- Applications

- for grain

- Technology

- chain

- Other characteristic

- flexible

Description

Circular chain conveyors are installed horizontally, or at an incline of up to 15° with no loss of performance. Through a combination of conveyor troughs and redirect stations, every point in a system can be reached. The circular chain conveyor consists of a 180° drive unit with chain tensioning unit, 90° redirect stations and moulded conveyor troughs up to max. 3m in length, into which inlets and outlets can be installed at any point.

Thanks to the trough's moulded shape and accordingly shaped carrier plates, no residue remains in the conveyor after changing materials. The conveyor chain is not exposed to the transported material, thus ensuring protection of the material during transport.

The ideal conveyor for seed companies, and for filling and emptying of silo systems!

-materials strictly separated and protected during transport

-flexible conveyor route design

-energy-efficient, as there is only one drive motor

-clockwise and anticlockwise operation possible

-modular design means your system can be expanded at any time

Other Horstkötter GmbH & Co. KG Tornado products

CONVEYORS

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.