Steel scraper 11027C5carbiderectangularfor packer roller

Add to favorites

Compare this product

Characteristics

- Material

- steel, carbide

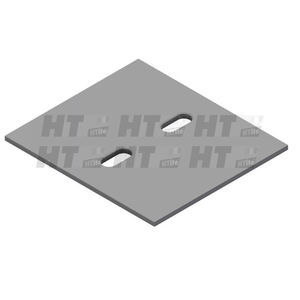

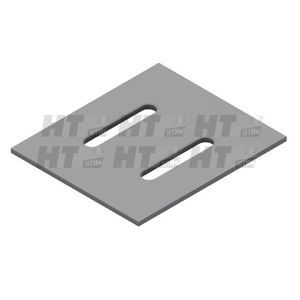

- Shape

- rectangular

- Application

- for packer roller

- Compatible brand

- compatible for Rabe

- Number of holes

- 1-hole

- Other characteristics

- coated

- Length

170 mm

(6.7 in)- Width

80 mm

(3.1 in)- Thickness

5 mm

(0.2 in)- Weight

0.55 kg

(1.213 lb)

Description

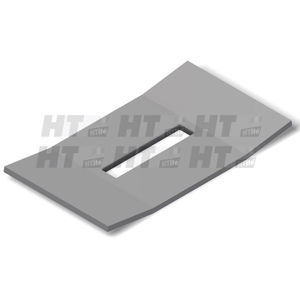

Scrapers for packer rolls with an HTite® tungsten carbide coating are ideal for heavy use as they are particularly resistant to abrasive wear.

The scraper for packer rolls is made of boron sheet steel, to which the HTite® coating is applied. The coating enhances the strength and durability of the scrapers for packer rolls, without altering their original geometry.

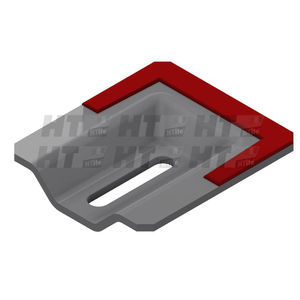

An HTite® coating with geometry “C” makes the scraper for packer rolls reversible as it is coated at both ends, but only on one face. For more information about the shape of the coating, check the attached figure in the item images.

The longer service life of scrapers for packer rolls coated in HTite® optimises roller cleaning because the tool maintains its original shape for a long time, reducing the frequency of checks, adjustments or replacement.

The alloy is deposited on the scrapers for packer rolls by means of technologically advanced industrial systems, which allow the HTite® coating to adhere perfectly to the substrate, making the treated part very strong and tough.

The HTite® coating is extremely compact, with a smooth, crack-free surface, an average matrix hardness of over 600 HV and carbide hardness of up to 2500 HV.

The HTite® coating is anchored securely to the metal of the treated component, completely eliminating total or partial detachment.

The durability of the tool and the high roller cleaning quality are benefits that make scrapers for packer rolls coated in HTite® a winning solution for your agricultural equipment.

Catalogs

No catalogs are available for this product.

See all of HT Srl‘s catalogsRelated Searches

- Scraper

- Scraper with hole

- Packer roller scraper

- 1-hole scraper

- Rectangular scraper

- 2-hole scraper

- Steel scraper

- Compatible for Amazone scraper

- Compatible for Kverneland scraper

- Compatible for Lely scraper

- Compatible for Maschio scraper

- Compatible for Rabe scraper

- Compatible for Lemken scraper

- Compatible for Howard scraper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.