- Farm Infrastructure

- Storage & Conveying

- Belt conveyor

- Josef Romberger Maschinenfabrik GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Belt conveyor

Add to favorites

Compare this product

Characteristics

- Technology

- belt

Description

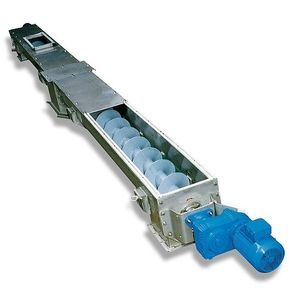

Romberger Belt Conveyors – Efficient. Durable. Custom-Made.

Our belt conveyors provide reliable solutions for the gentle and efficient transport of bulk materials in industrial and agricultural settings. With their robust design, modular construction, and flexible configuration, they are easily adapted to your specific needs.

Your Advantages:

- Strong construction for high loads

- Modular design – easy to maintain and install

- Low-wear transport with reduced conveying speed

- Tailored systems for every application

- Quiet operation for a better work environment

- Wide range of uses across many industries

- Long-term service and support

Key Technical Data:

- Capacity: 1–500 m³/h

- Belt widths: 100–1500 mm

- Inclination: 0–20° (standard), up to 90° with cleated or special belts

- Designs: Flat, trough, dosing, sack, plastic or hinged belt conveyors

- Materials: Galvanized or stainless steel

- Drive: Maintenance-free drum motor (IP67) or gear motor

- Safety: Speed monitoring, pull-cord switch, belt misalignment control

Optional Features:

- Tracking rollers, belt scales, magnetic drums, metal detectors

- Reversible, adjustable, telescopic, or swivel conveyor designs

- Quick-change belt scrapers for easy cleaning

Romberger – Your partner for durable conveyor technology, engineered in Germany.

Catalogs

No catalogs are available for this product.

See all of Josef Romberger Maschinenfabrik GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Josef Romberger Maschinenfabrik GmbH products

Conveying technology

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.