- Farm Machinery

- Tillage

- 5-rows ridger

- Machinefabriek STEKETEE B.V.

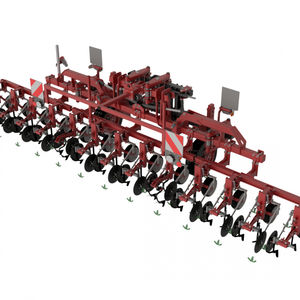

5-rows ridger EC-RIDGERpotatocarrotdisc

Add to favorites

Compare this product

Characteristics

- Number of rows

- 5-rows

- Crop type

- potato, carrot

- Type

- disc, mouldboard

- Other characteristic

- rigid

- Width

6 m

(19'08" )

Description

The EC-Ridger is suitable for all crops grown on ridges with 75 cm row distance, like potatoes and carrots, also in later growing stages.

The working principle of the EC-Ridger consists of three to five steps: Optionally, the subsoiler cultivates the soil between the ridges. Then the hoeing discs cut the weeds from the sides of the ridge and the spring tines loosen the soil between the ridges. At the end of the process, the earthing-up rebuilds the ridge back into its shape. Optionally, a metal plate protects the crop leaves from damage.

-Working width up to 6 m

-Driving speed up to 8 km/h

-Row distance 75 cm

-Automatic & manual steering systems

COMPONENTS

SUBSOILER

The optional subsoiler loosens the soil between the ridges and supports the water drainage. The working depth can be individually adjusted.

TRS-ELEMENT

The heavy one: The TRS-Element is well suited for severe conditions. Therefore it is used in the EC-Ridger machines for earthing-up shares and other heavy tools.

HOEING DISCS

The hoeing discs cut the weeds from the sides of the ridges, the cutting angle and the width can be easily adjusted to fit the ridge.

SPRING TINES WITH SHARES

The spring tines with shares loosen the soil between the ridges.

EARTHING-UP SHARES

The earthing-up share rebuilds the ridge back into its shape. The angel can be adjusted to fit the ridge and to control the compactness of the ridge.

EARTHING-UP DISC

Instead of the earthing-up share, it is also possible to use earthing-up discs. They are especially suitable for wet conditions and certain soils.

Catalogs

No catalogs are available for this product.

See all of Machinefabriek STEKETEE B.V.‘s catalogsOther Machinefabriek STEKETEE B.V. products

WEEDING TECHNOLOGY

Related Searches

- Stubble cultivator

- Mounted stubble cultivator

- Stubble cultivator with roller

- Plough

- Mounted plough

- Rigid tine stubble cultivator

- Folding stubble cultivator

- Plough with hydraulic adjustment

- Furrow plough

- Towed stubble cultivator

- Adjustable-width plough

- Hiller

- Stubble cultivator with disk harrow

- 4-shank plough

- Vegetable ridge former

- 5-shank plough

- Chisel plough

- Disc ridger

- Potato hiller

- Plowshare ridger

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.