- Farm Machinery

- Crop protection & maintenance

- Mechanical weeder

- Machinefabriek STEKETEE B.V.

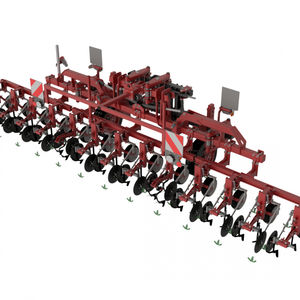

Mechanical weeder IC-WEEDERmounted

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- mechanical

- Mobility

- mounted

Description

This is how your IC-Weeder for lettuce could look like. It covers 5 rows with a row distance of 28 cm. Underneath the cover are 3 cameras mounted for the single plant recognition. The field of vision is illuminated with LED lights. A compressor provides the pneumatic pressure to move sickle-shaped knifes actively intra-row, so between the plants in one row. The inter-and intra-row tools are mounted on an parallelogram-element to follow the contour easily. The support wheels guarantees the correct working depth of the knifes, and via the side shift-frame the machine is steered precisely between the rows.

Find out all your options to customize your IC-Weeder for your needs:

-Row width minimum 25 cm

-Plant distance minimum 15 cm

-Working width up to 6 m

-Driving speed up to 3 km/h

-Weeding up to 2 cm close to the crop

-Multiple cameras covering 75 cm field of vision each

-Detection of green hues and the RGB-colour spectrum

-Remote service for direct suppor

COMPONENTS

CAMERA

The cameras are covered to avoid shades through natural sunlight. Instead, the field of vision is illuminated with LED-lights, for high quality camera images. The camera makes high resolution pictures in green hues or the RGB-colour spectrum, every camera covers a field of vision of 75 cm. The images are transferred to the job computer and visualized on the terminal.

JOB COMPUTER

The job computer processes the camera-images to precise steering signals. The crop position is calculated on base of the camera image, the crop size and the expected plant position.

Catalogs

IC-Weeder

8 Pages

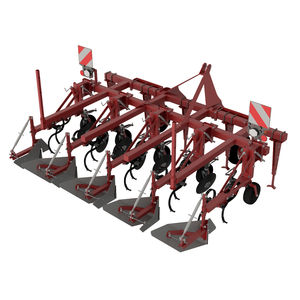

Hoeing equipment

28 Pages

Other Machinefabriek STEKETEE B.V. products

WEEDING TECHNOLOGY

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.