Color sorter S 1000tomatofruitautomatic

Add to favorites

Compare this product

Characteristics

- Crop type

- tomato, fruit

- Technology

- color

- Other characteristics

- automatic

Description

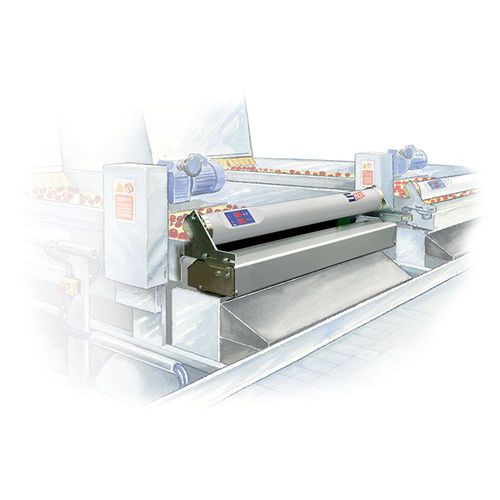

Optical sorters of “S1000” series are manufactured on carbon frames, and they are one-of-a-kind.

1.The use of this innovative material is determined by significant needs:

2.To reduce dimensions, thus allowing for applications that otherwise would be very difficult or impossible.

3.To lower weights that allow the sorter to be handled very easily.

A very high resistance to almost all corrosive agents, thus rendering the sorter structure almost indestructible.

4.High resistance to impacts.

Operating principle

All optical sorters are equipped with the innovative scanning viewing system of color and material. This instrument – fruit of in-depth research studies – assures a very accurate sorting to the user.

Fruits are distributed onto the machine feeding belt to be then scanned by the video cameras placed so as to cover the whole belt width. In fractions of one thousand of a second the material is viewed by the system and declared to be “suitable” or “unsuitable”. Should the latter be the case, it is rejected by the smart ejectors positioned on the lower pneumatic unit which hit the polluting material with a millimetric precision by ejecting it. All the suitable material is saved and goes on toward the following stations.

Catalogs

No catalogs are available for this product.

See all of MTS srl‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.