- Farm Infrastructure

- Storage & Conveying

- Grain conveyor

- Mysilo (Siloport)

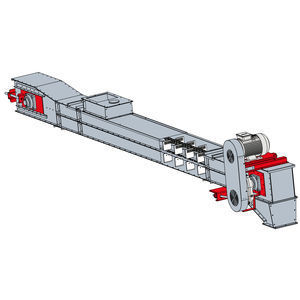

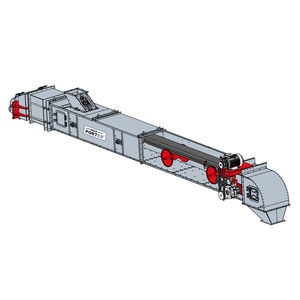

Chain conveyor HI Seriesfor grain

Add to favorites

Compare this product

Characteristics

- Applications

- for grain

- Technology

- chain

Description

HI Series conveyors are used to elevate grains at an angle between 10° and 70° after horizontally conveying them over a specific distance. These conveyors are preferred for locations with inclined loading and unloading areas or where the angle is too steep for standard chain conveyors.

Capacity:

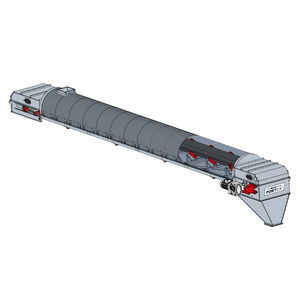

The HI Series conveyors come in various models and product options with capacities ranging from 70 m³/h to 390 m³/h.

Structural Features:

All HI Series conveyors are manufactured from galvanized sheet metal and assembled using only bolt and nut connections. They have a long service life. Optional reinforcement with polyethylene sheets or wear-resistant steel plates can be added to the base and side surfaces for extended conveyor lifespan.

The operational approach of these conveyors differs from the Y models. While the area utilized for conveying grains in standard conveyors is around 80-85%, it's approximately 40% for this type of conveyor. This results in a specific capacity requirement and the use of a broader body. The pallets carrying the grain and the associated supports are different from standard conveyors. The motor power requirements for HI Model conveyors are higher compared to Y model conveyors of the same length and capacity. The required power in these conveyors can vary based on numerous parameters.

Catalogs

No catalogs are available for this product.

See all of Mysilo (Siloport)‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.