- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

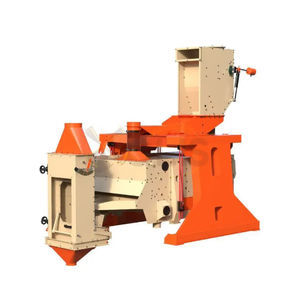

Grain pre-cleaner SКО-100Rotary drumseparator

Add to favorites

Compare this product

Characteristics

- Application

- for grain

- Type

- Rotary drum

- Other characteristics

- separator

Description

The initial product enters the drum, the sieves of which pass the grain and retain the garbage that comes out at the end of the cylinder. The use of the scalperator (pre-cleaner) is necessary to ensure normal during operation, prevent them from clogging and reduce energy consumption spent on drying the product, as well as for the selection of random objects that can lead to breakdowns of conveyance. Selection of the diameter of the perforated holes of the sieves depends on the processed grain, its moisture content and the type of impurities to be removed. If necessary, the first sieves can be used to remove fine impurities.

The rotary drum scalper can be equipped with an air separator (aspirator) with a closed air cycle VSZ, which is mounted on the skalperator on the grain separator LUCH ZSO principle.

In order to operate the grain cleaning scalperator with the air separator VSZ, it is additionally necessary to install the cyclone, a fan, the control panel and the air ducts.

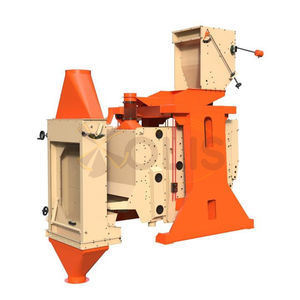

To simplify installation work and for the most efficient operation of the skalperator, the company OLIS has developed an aggregate solution skalperator SKO-100А.

Grain aggregate rotary drum scalper SKO-100А consists of: rotary drum scalper SKO-100, air separator with a closed air cycle VSZ, cyclone with sluice gate and drive, fan, ducts, control panel, cables, trays and ladders.

Аdvantages

1. High technological efficiency due to the large area of the operating surface of the sieves and possibility of installing them independently depending on the specific operating conditions;

2. Metal-bearing, wear-resistant construction;

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.