- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

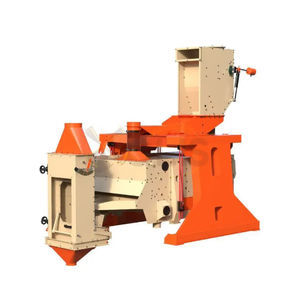

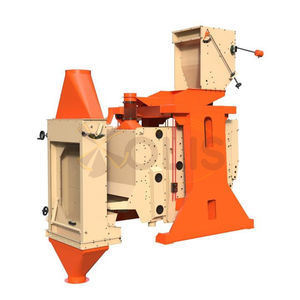

Destoner OMP-3

Add to favorites

Compare this product

Description

manufactured by OLIS Ltd are used for effective separation of mineral impurities from grain flows at grain enterprises.

The destoner works as follows: under the combined influence of the vibrations of the sorting surface and the air flow, grain is loosened, while the coefficient of internal friction decreases, and the grain mixture enters a state of fluidization. In the presence of an aerating effect, the fluidized layer of grain, which is practically not prone to the transport of the deck, flows as a “liquid” down the slope and is unloaded in the lower, wide part of the deck. Heavy mineral particles, which are in the lower layer and have the greatest adhesion to the rough sorting surface, are transported up against the inclination of the deck and are discharged through the upper narrowed part.

Specifications

Productivity (of wheat), t/h - 6,0

Efficiency of cleaning grain from mineral impurities, % - 99

Pre-installed electric power capacity (without fan), kW - 0,9

Air consumption, m3/h - 2500

Aerodynamic resistance, Pa - 750

Weight, kg - 255

Overall dimensions, mm

length 1900

width 900

height - 1745

VIDEO

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.