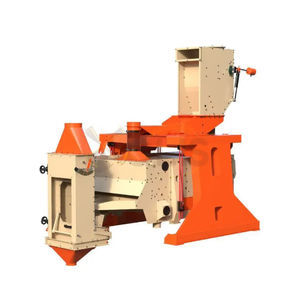

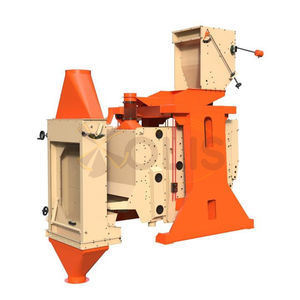

Grain sorter ТCK-500rotary drumwith aspiratorautomatic

Add to favorites

Compare this product

Characteristics

- Crop type

- grain

- Technology

- rotary drum, with aspirator

- Other characteristics

- automatic, with cleaning system, seed length

Description

Indented сylinder ТCK-500 is intended for cleaning the grain of the main crop from short impurity cockle. It is also used to sort cleaned grain by length.

Scope of application:

Indented cylinders ТCK-500 used in elevators, flour mills and groats mills to separate cockle seeds from grain mixtures; at groats factories – for separating oats from barley and separating hulled and unhulled grains. And also at seed processing plants and corn seed calibration plants to select the largest grains from a mixture.

Operation description:

Main movable object of the indented cylinder is a cylinder with cells where short fractures (cockle) are proceeded and long fractures (graint), which are longer than cells, are not proceeded into cells. The cell cylinder rotates and discharges long fractures on the first tray. Short fractures are discharged on the second tray. This is how the mixture is fractionated.

Specifications

Productivity up to, kg/h - 2500

Cleaning efficiency, not less, % - 80

Pre-installed electric power capacity, kW - 0,75

Power supply characteristics:

Voltage, V 380

Frequency, Hz - 50

Air consumption for aspiration, m3/h - 300

Aerodynamic resistance, Pa - 400

Overall dimensions, mm

length 2800

width 1100

height - 1400

Weight, not more, kg - 600

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Grain elevator

- Stationary dryer

- Cereal dryer

- Grain grinding mill

- Screw elevator

- Feed elevator

- Automatic sorting machine

- Hammer grinding mill

- Seed sorting machine

- Stationary grinding mill

- Roller grinding mill

- Bucket elevator

- Vegetable sorting table

- Fruit sorting table

- Dust collector

- Fixed dryer

- Grain sorting machine

- Processing line

- Feed-mill unit

- Vertical bucket elevator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.