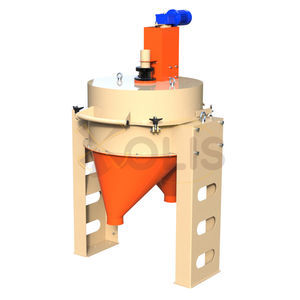

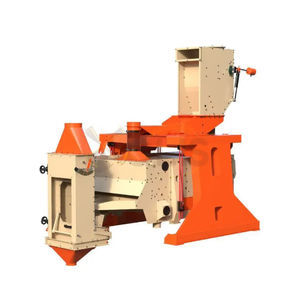

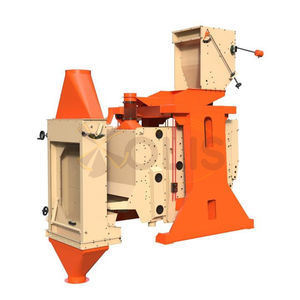

Plansifter RKO-4

Add to favorites

Compare this product

fo_shop_gate_exact_title

Description

Self-balancing plansifter RKO-4 is designed for selection of intermediate products of hulling and grinding, sorting and control of products at enterprises of groats industry.

The principle of plansifter RKO-4 operation consists in parallel and sequential sieving of the product through a set of flat horizontal sieves that perform a circular translational motion. The initial product, by means of gravity transport, enters the receiving box, where it is separated into sieve frames.

Specifications

Rated pre-installed power, kW - 3,0

Frequency of circular vibrations of the body, s-1 (rpm) - 160

Radius of circular vibrations of the body, mm - 35

Sifting surface area, m2 - up to 20

Number of frames in a section, pcs. - up to 20

Number of sections, pcs. - 4

Weight, kg - 1000

Overall dimensions, mm

length 1750

width 1750

height 2300 -

Аdvantages

1. Lack of dynamic loads on the floor;

2. Weight of the plansifter in running order is two to three times less than that of analogues;

3. The body of the plansifter and sieve frames is made of aluminum and stainless steel, which meets modern sanitary and epidemiological requirements;

4. Hermetic manufacturing does not require aspiration;

5. No contaminations;

6. Convenience and ease of replacement of sieves, which ensures minimal time spent when switching to other numbers of sieves;

7. Highly efficient sieve cleaning, allowing the use of the entire sifting surface;

8. Components from leading European manufacturers are used;

9. The use of modern materials that can significantly increase the service life of the plansifter;

10. Possibility of installation of sieving in premises with a height of 2.5 m.

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Grain elevator

- Stationary dryer

- Cereal dryer

- Grain grinding mill

- Screw elevator

- Feed elevator

- Automatic sorting machine

- Hammer grinding mill

- Seed sorting machine

- Stationary grinding mill

- Bucket elevator

- Roller grinding mill

- Vegetable sorting table

- Fruit sorting table

- Dust collector

- Fixed dryer

- Grain sorting machine

- Processing line

- De-awner

- Vertical bucket elevator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.