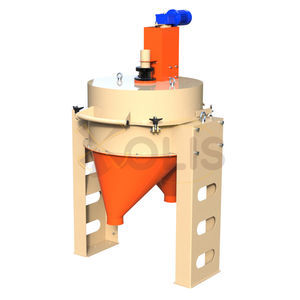

Air separator ASOgrain

Add to favorites

Compare this product

Characteristics

- Applications

- grain

- Type

- air

Description

Purpose and scope of application:

Air separator ASO is designed to separate particles which differ in their terminal velocity. As a rule, separators of this design are used when it is necessary to ensure high efficiency and clarity of separation, for example, for separating the products of hulling groats, controlling finished products, husks, etc.

The initial product enters the pneumoseparating channel of the air separator, where it is blown by an ascending air flow created by a crossflow fan. The purified product is taken out of the machine by gravity. Light impurities trapped in the air are separated in the settling chamber and removed by means of the auger and the discharge valve, and the air is fed into the pneumatic separating channel for subsequent use.

Аdvantages

1. High separation efficiency and clarity;

2.Closed air use cycle, contributing to a significant reduction in emissions into the atmosphere as a whole, as well as energy saving for heating during the cold season;

3. High reliability and maintainability, provided by a simple design and the use of special components;

4. Convenient adjusting nodes that allow you to very accurately adjust the supply of product and air;

5. The loading device evenly distributes the product before feeding into the separation zone, which ensures an optimal product separation process.

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.