- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

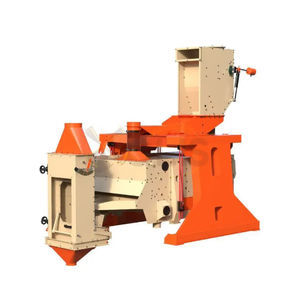

Grain pre-cleaner LUCH ZSO-200Rotary drumseparator

Add to favorites

Compare this product

Characteristics

- Application

- for grain

- Type

- Rotary drum

- Other characteristics

- separator

Description

Rotary cleaning machine “LUCH” ZSO-200 consists of sieve and air separators (Fig. 1). The initial grain enters the air separator with a closed air cycle VSZ-160, where it is blown by a counterflow of air, while light impurities are separated. After that, the grain, cleaned of light impurities, enters the sieve drum, where it is cleaned of impurities which differ in size. The obtained fractions of cleaned grain, fine and coarse impurities are separately removed from the machine through the outlet nozzles. Sieves are cleaned by blocks of moving brushes and rollers.

Grain cleaning on sieves (in sieve drum separator) occurs by sieving through a rotating sieve drum according to one of selected cleaning schemes.

To operate the rotary drum cleaner LUCH ZSO-200 with the air separator VSZ-160, it is additionally necessary to install a cyclone, a fan, a control panel and air ducts.

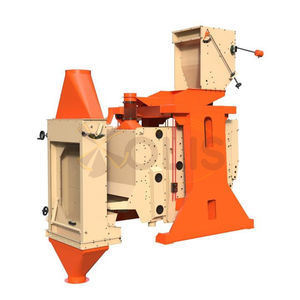

In order to simplify installation work and ensure the most efficient operation of the sieve-air separator, the company OLIS has developed an aggregated solution of LUCH ZSO-200A.

Rotary aggregate drum cleaner LUCH ZSO-200А includes rotary drum cleaner LUCH ZSO-200, air separator with a closed air cycle VSZ-160, cyclone UCO-900 with sluice gate and drive, fan, air ducts, control panel, cables, trays and ladders.

VIDEO

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.