- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

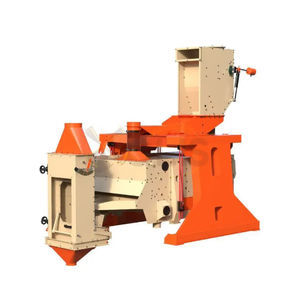

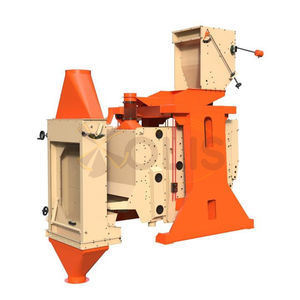

Grain pre-cleaner HORIZONT-К-500vibrating meshwith cycloneseparator

Add to favorites

Compare this product

Characteristics

- Application

- for grain

- Type

- vibrating mesh, with cyclone

- Other characteristics

- separator, with aspirator

Description

Screen Cleaner “HORIZONT-K-500” is designed for grain cleaning from coarse, fine and light impurities in grain elevators, mills and other grain processing facilities. The separator ensures the following operations: preliminary cleaning, primary cleaning, secondary cleaning (sorting, calibration).

Application:

Screen cleaner “HORIZONT-K-500” is designed for grain cleaning from coarse, fine and light impurities in grain elevators, mills and other grain processing facilities. The separator ensures the following operations: preliminary cleaning, primary cleaning, secondary cleaning (sorting, calibration).

The screen cleaner “HORIZONT-K-500” can be equipped with an air separator with a closed air cycle VSZ-200, an air separator with a closed air cycle VSZM-200, as well as an aspiration column KAO-200.

Аdvantages

1.High productivity with a small area occupied by the separator;

2.Effective grain cleaning due to large area of operating surface of sieves;

3.Design reliability and ease of use;

4.Use of simple, reliable and highly effective means of cleaning sieves;

5.Possibility of organizing a double air separation of grain (at the entrance to the sieve body and at the exit from it) with the additional installation of an air separator VSN or an air separator VSZ;

6. Low power consumption.

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.