- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

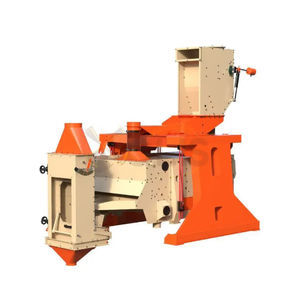

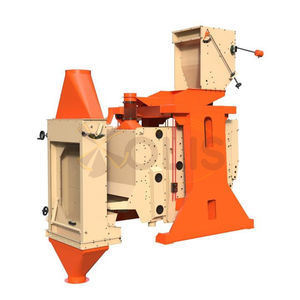

Air separator VSZM-200graingravitywith pre-cleaner

Add to favorites

Compare this product

Characteristics

- Applications

- grain

- Type

- air, gravity

- Other characteristics

- with pre-cleaner

Description

Air separator VSZM-200 is designed for grain cleaning from impurities which differ in their aerodynamic properties. It can be used in grain storages, flour mills, feed mills and groats mills.

Air separator VSZM-200 is made with a closed air cycle, without installation of an external fan, a cyclone and air ducts, which contributes to a significant reduction of production emissions into the atmosphere in general, as well as energy savings for heating in the cold season.

Operation description:

Initial product enters the aspirating channel of the air separator where it is ventilated by the upward flow of the air created by tangential flow fan. Purified product is discharged from the machine by gravity. Light impurities are separated in the sediment chamber and removed via the screw conveyor and the air is supplied to the aspirating channel for later use.

Specifications

Throughput productivity*, t/h - up to 300

Pre-installed electric power capacity, kW - 12,5

Length of the operating channel, mm - 2000

Weight, kg - 2295

Overall dimensions, mm

length 2710

width 3600

height - 4900

Аdvantages

1. It has a closed air cycle, due to which there is no need for air ducts and cyclones for cleaning exhaust air;

2. There are no emissions of exhaust air into the atmosphere;

3. High degree of grain cleaning;

4. Coarse and precise air adjustment is provided, which achieves smoothness of adjustment, which allows to achieve high-quality cleaning of all types of grain;

5. Use of components from leading European manufacturers.

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.