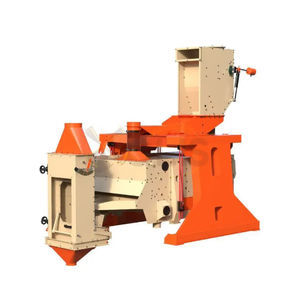

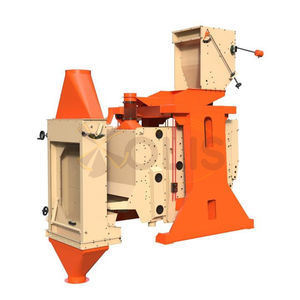

Seed sifter machine BM seriesdrum

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- seed

- Other characteristics

- drum

- Length

1,520 mm, 2,000 mm, 2,922 mm

(59.8 in, 78.7 in, 115 in)- Width

840 mm, 938 mm, 1,270 mm

(33.1 in, 36.9 in, 50 in)

Description

Sieving machine BM, manufactured by OLIS Ltd, is designed for sorting hulling and grinding products, as well as for monitoring waste and finished products in the grinding departments of flour mills and groats mills.

The machine consists of the body, the drive and the rotor with two sieve drums. The product entering the machine through the inlet pipe is fed by the auger into the sieve drum, where it is separated into two fractions. The bypass product enters the second sieve drum, where separation also takes place. The obtained fractions are separately removed from the machine through the outlet pipes. Sieves are cleaned using inertial cleaners and brushes.

Аdvantages

1. Separation of the product into four fractions;

2. No contaminations;

3. Convenience and ease of replacement of sieves;

4. Use of components from leading European manufacturers;

5. Efficient sieve cleaning.

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.