- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Electric power heating system PZ seriesfor grain storage

Add to favorites

Compare this product

Characteristics

- Power source

- electric power

- Application

- for grain storage

- Power

1.1 kW

Description

Grain heaters PZ are designed for grain heating in cold season. It is used in mills where graded flour is produced.

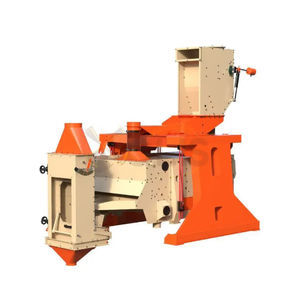

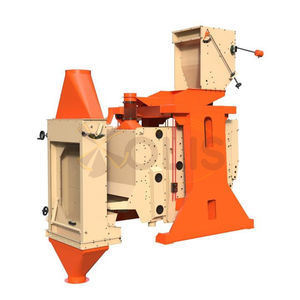

Heater (Fig. 1) consists of a receiving hopper (Pos. 1), one or several heating sections (Pos. 2) and outlet pipes (Pos.3). Heating section (Fig. 2) is a construction shaft type with rectangular cross-section 1000×1000 mm and length of 2000 mm. A heating element is made of straight segments of a pipe connected to a coil. Its welded joints are located outside a shaft. A body section is provided with manholes for the access into heater and lids that cover joints of heating pipes. An outlet pipe includes a design of outlet funnel excluding formation of stagnant zones in heating section, as well as a rotary discharger with a drive. All external heating elements of heater are insulated. Water is used as a heat carrier which is heated in a boiler of any type and is proceeded through a heating element in a closed circuit. One heating section is designed with productivity of 1500 kg/h. If, productivity is necessary to increase, the required number of sections is set consistently, mounting them vertically with the help of flanged connections.

Grain to be heated is proceeded into the hopper and enters by gravity flow the heating section. As a result of contact with a hot surface grain is heated. Grain is discharged from the machine through the outlet pipe and the rotary discharger. The grain heater is equipped with the control switchboard with the frequency transducer. The frequency transducer adjusts numbers of revolutions of the rotary discharger in the outlet of the machine and time of grain staying in the heater.

Catalogs

No catalogs are available for this product.

See all of OLIS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.