- Livestock Farming

- Milking equipment

- Cows milking cluster

- Onfarm Solutions Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Cows milking cluster Cotswold4 teat cups2 teat cups

Add to favorites

Compare this product

Characteristics

- Animal type

- cows

- Number of teat cups

- 4 teat cups, 2 teat cups

Description

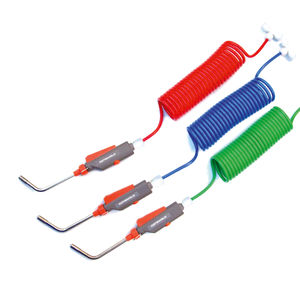

The Cotswold Automatic Cluster Flush

The Cotswold Automatic Cluster Flush system is a very effective way of sanitizing the milking units between cows and so minimising the transfer of contagious mastitis organisms, with a clean cluster on every cow.

The process is fully automatic, individual unit flushing being initiated by the cluster remover on swingover herringbone, rotary and most other parlours and whole side flushing by the vacuum gate controls, on doubled up herringbone parlours. Doubled up herringbones can alternatively be operated by a separate push button (one per side) if required.

Once it is activated by the vacuum signal, the cluster flush control module completes the cycle of two flushes, (water and peracetic acid 0.5%) leaving the cluster ready to put on the next cow.

The unique liquid/pressure cylinder, designed and manufactured by Cotswold, means that unlike other systems on the market, no water/peracetic acid mix goes through the solenoid valves, only compressed air. This makes for a much more reliable system and cuts down on expensive solenoid valve replacements.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.