- Farm Management

- Precision agriculture

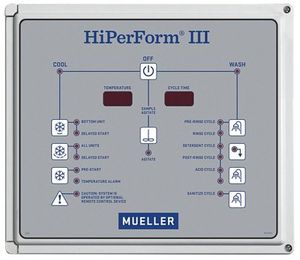

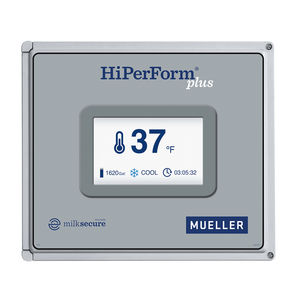

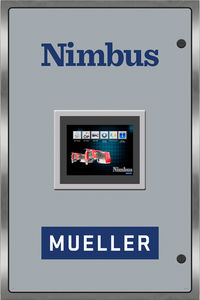

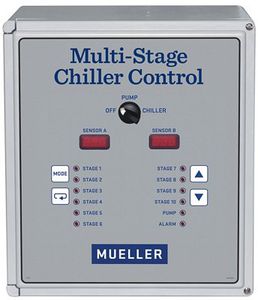

- Milk tank control system

- Paul Mueller Company

Milk tank control system RIC

Add to favorites

Compare this product

Characteristics

- Application

- for milk tanks

Description

Milk Cooling has Evolved

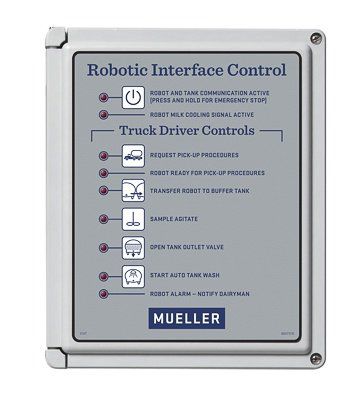

Robotic milking systems continue to become more prevalent in dairy farms around the world. Until now, there has not been a control which communicates between cooling and wash controls, and the robot. We're proud to introduce our latest control, the Robotic Interface Control.

Leading the herd.

When we set out to design and build the Robotic Interface Control, our goal was to continue the automation from the robotic end into our controls to simplify procedures. Our Robotic Interface Control was developed as the one stop control box for the milk hauler. The milk hauler now has the ability to start his pickup procedure at the press of a button, allowing the control to take care of the rest.

RIC Features and Benefits

- Simple point of contact for pickup procedures.

- Smart I/O board simplifies interface between thecooling and was control, and the robotic milking system.

- Smart I/O board contains 8 outputs with bothnormally open and normally closed relays.

- Pre-programmed high temperature alarm outputnotifies robot of high product temperature.

- Intuitive control overlay ensures ease of usefor all users.

- LED indicators display the current controloperation.

- Industrial grade high-speed microprocessorallows for fast communication between the robotic milking system, and thecooling and wash control.

- Utilizes robust RS485 communication.

- Plug and play installation enables the hardwareto take control of the rest.

Catalogs

No catalogs are available for this product.

See all of Paul Mueller Company‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.