- Livestock Farming

- Livestock equipment

- Horizontal mixing wagon

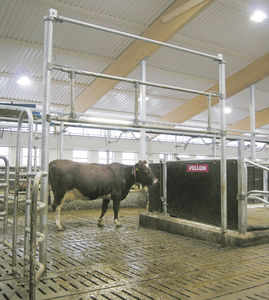

- Pellon Group Oy

Horizontal mixer Pro FDstationary

Add to favorites

Compare this product

Characteristics

- Auger orientation

- horizontal

- Mobility

- stationary

- Capacity in m³

16.9 m³, 20 m³, 27 m³

(596.8 ft³, 706.3 ft³, 953.5 ft³)

Description

The new Module Pro range varies in capacity from 17 to 27 cubic metres. They range in length from 6.25 to 10 metres. Module Pro devices are simpler than their predecessors, which gives them a longer service life.

As in the larger Module HD range, the conveyor chains are zinc-coated roller chains that are protected inside closed channels. Another advantage of using a roller chain is that there is no limit to how far the conveyor can be reversed, allowing the filling device to be filled entirely at any time. The conveyor’s scrapers travel along slides made out of recycled plastic. The conveyors of the new filling devices use two chains instead of the four used in previous models. Using two chains ensures that the chains are loaded evenly and the device is more reliable.

The closed-bottom design of the filling device makes it easier to keep the feed room tidy, allowing for water and silage effluent to be drained cleanly to one point on the feed room floor.

Module Pro filling devices can be equipped with the Pellon Silage Ripper or Twin Ripper.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.