- Farm Infrastructure

- Building equipment

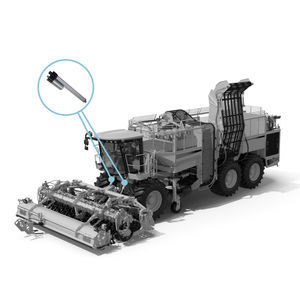

- Electric cylinder

- Progressive Automations Inc

Electric cylinder linearfor harvestersuniversal

Add to favorites

Compare this product

Characteristics

- Type

- electric

- Movement

- linear

- Tool application

- for harvesters

- Brand compatibility

- universal

Description

Actuators in harvesters enable precise adjustments of functions like spout adjustments and reel positioning, streamlining operations and improving performance.

CHALLENGES

Electric linear actuators in harvesters face environmental exposure, heavy load handling, precision maintenance, power supply requirements, and integration complexity. Dust, moisture, and temperature fluctuations can degrade performance. Heavy loads increase mechanical stress, and maintaining precision is difficult due to wear and calibration drift.

SOLUTIONS

Protect actuators with enclosures and IP-rated seals to shield from elements. Use robust materials for heavy load handling and high-resolution sensors for accuracy. Optimize power management with efficient motors and algorithms. Ensure compatibility with agricultural machinery protocols and provide thorough documentation and testing for seamless integration.

BENEFITS

Electric linear actuators enhance combine and forage harvesters by providing precise control, improving energy efficiency, and requiring less maintenance. Their compact design increases maneuverability, while their integration with automation systems and reduced environmental impact align with modern agricultural and sustainability goals.

Other Progressive Automations Inc products

Agriculture & Farming

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.