- Farm Infrastructure

- Building equipment

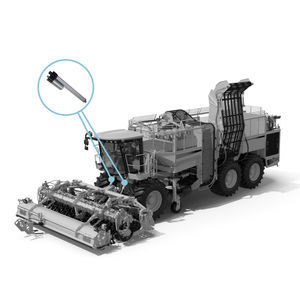

- Electric cylinder

- Progressive Automations Inc

Electric cylinder linearfor crop sprayersuniversal

Add to favorites

Compare this product

Characteristics

- Type

- electric

- Movement

- linear

- Tool application

- for crop sprayers

- Brand compatibility

- universal

Description

Electric linear actuators play a vital role in agricultural spreaders by enabling precise control over material distribution rates, ensuring uniform application across fields. Their integration automates key functions and incorporates advanced safety features, enhancing operational efficiency and safety in agricultural practices.

CHALLENGES

Navigating challenges in agricultural spreaders using electric linear actuators involves ensuring durability against dust and debris ingress, corrosion from moisture exposure, handling heavy loads, withstanding extreme temperatures, mitigating vibration and shock, ensuring power supply reliability, maintaining precision and accuracy, seamless integration with control systems, optimizing energy efficiency, and minimizing maintenance and downtime.

SOLUTIONS

Solutions for challenges in agricultural spreaders with electric linear actuators include sealed designs with high IP ratings to prevent dust and debris ingress, and moisture protection. Robust construction for heavy loads, temperature-resistant components, shock-absorbing mechanisms, backup power solutions, high-precision sensors for accuracy, standardized communication protocols for integration, energy-efficient designs, and predictive maintenance features for minimal downtime.

BENEFITS

Electric linear actuators offer precise control, automation, safety features, reliability, energy efficiency, low maintenance, and quiet operation for agricultural spreaders.

Other Progressive Automations Inc products

Agriculture & Farming

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.