- Farm Infrastructure

- Building equipment

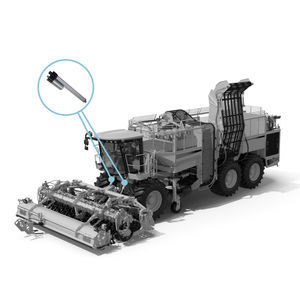

- Electric cylinder

- Progressive Automations Inc

Electric cylinder linearfor crop sprayers

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- electric

- Movement

- linear

- Tool application

- for crop sprayers

Description

Actuators in agricultural sprayers ensure precise spray distribution, improving crop management and reducing waste. This leads to higher productivity and supports sustainable farming by maximizing crop protection efficiency

CHALLENGES

Agricultural sprayers face several challenges with linear actuators, including corrosion from chemicals, vibration and shock from rough terrain, extreme temperature variations, contamination from dust and debris, and the need for high-pressure operation. These issues can compromise the functionality, durability, and performance of the actuators.

SOLUTIONS

To address these challenges, use corrosion-resistant materials like stainless steel or aluminum, design robust structures with shock-absorbing features, incorporate temperature-resistant components and thermal management. Employ effective sealing mechanisms and utilize seals capable of withstanding high pressures. Regular maintenance and testing ensure reliability and optimal performance under various operating conditions.

BENEFITS

Electric linear actuators are essential for agricultural sprayers due to their precision control, efficiency, adaptability, and low maintenance. They offer quiet operation, energy efficiency, remote control capability, durability, safety features, and consistent performance, leading to optimized spray patterns and enhanced crop management.

Other Progressive Automations Inc products

Agriculture & Farming

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.