- Farm Infrastructure

- Building equipment

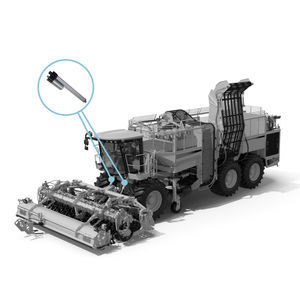

- Electric cylinder

- Progressive Automations Inc

Electric cylinder linearfor seed drills

Add to favorites

Compare this product

Characteristics

- Type

- electric

- Movement

- linear

- Tool application

- for seed drills

Description

Electric linear actuators enhance seeding equipment by precisely controlling seed placement, depth, and spacing. Their integration streamlines operations, reduces manual adjustments, and ensures uniform crop emergence, leading to safer and more efficient farming practices.

CHALLENGES

Addressing challenges in seeding equipment utilizing electric linear actuators encompasses various technical hurdles such as dust and debris ingress, moisture exposure, heavy load handling, extreme temperatures, power supply reliability, vibration and shock, control precision, and energy efficiency. Each challenge necessitates meticulous solutions to ensure seamless operation and longevity in agricultural settings.

SOLUTIONS

Solutions involve sealed designs with high IP ratings to prevent debris and moisture ingress, corrosion-resistant materials for longevity, robust construction for heavy loads, and temperature-resistant materials. Stable power supply, shock-absorbing mechanisms, high-resolution feedback systems, and energy-efficient designs optimize performance in agricultural settings.

BENEFITS

Electric linear actuators offer precise control, automation, and safety for agricultural seeding equipment. They ensure consistent seed placement, increase operational efficiency, and enhance operator safety. With advanced sensors, they provide real-time monitoring, lower energy consumption, require less maintenance, and operate quietly, benefiting both operators and livestock.

Other Progressive Automations Inc products

Agriculture & Farming

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.